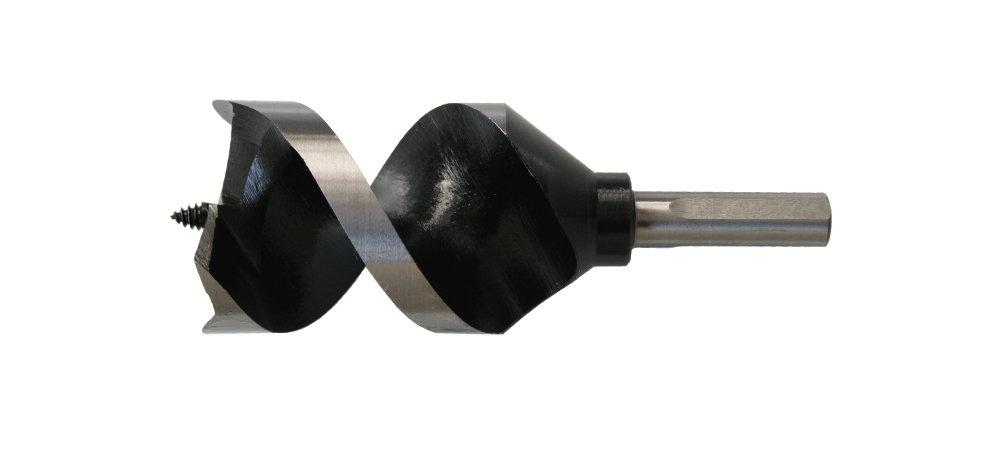

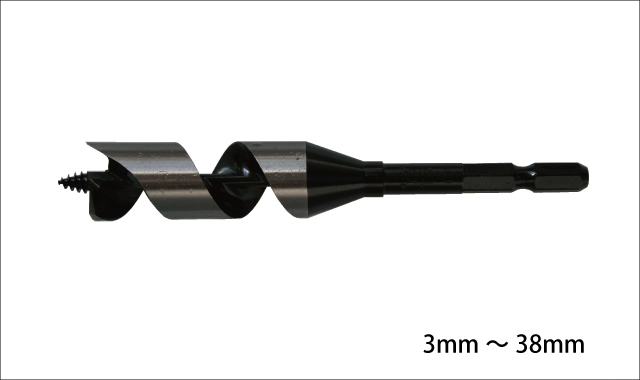

No.5 Combination Short Auger Bit

Shallow boring

- Burr-free lead screw for quick, on-target starts & smooth cutting.

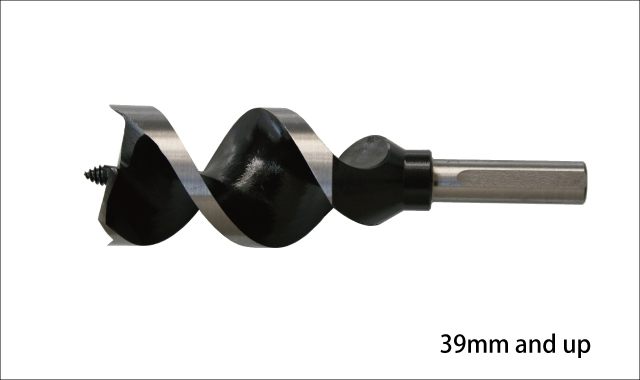

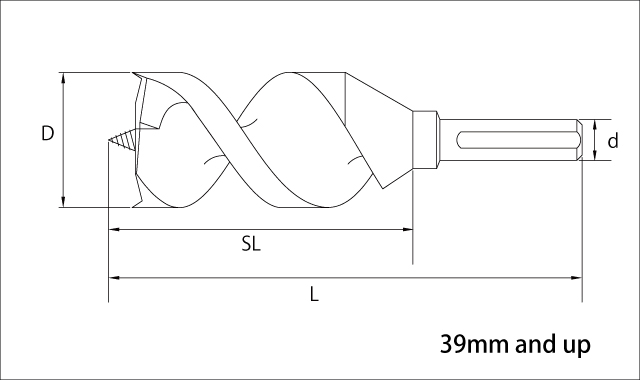

- 39mm and larger utilize double spurs and double twists for minimum resistance.

Specifications

| Usage | Wood |

|---|---|

| Material(s) | High Carbon Steel |

| Recommended tool(s) | Electric Power Drill Quick Change Impact Driver(Less than 19mm)(over 14.4V) |

| RPm Range | 3mm~19mm:Less than 3,000rpm 19.5mm~40mm:Less than 1,500rpm 41mm and up:Less than 1,300rpm |

| Shank Shape |  :Hexagon :Hexagon  :Three Flats :Three Flats |

Sizes

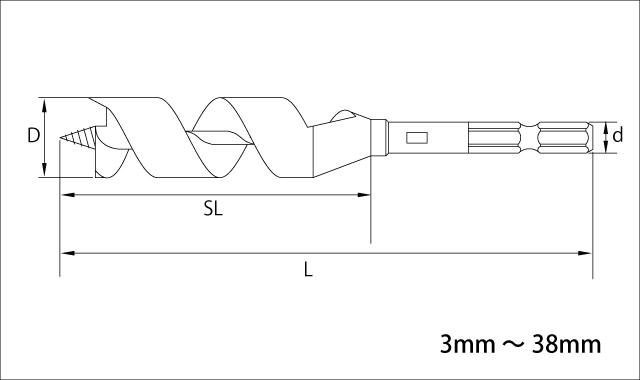

Size:D Overall Length:L Spiral Length:SL Shank Shape:d unit:mm

Single Item

| Product No. | Size | Overall Length | Spiral Length | Shank Shape |

|---|---|---|---|---|

| 5-030 | 3 | 80 | 45 | 6.35  |

| 5-035 | 3.5 | 80 | 45 | 6.35  |

| 5-040 | 4 | 80 | 45 | 6.35  |

| 5-045 | 4.5 | 90 | 50 | 6.35  |

| 5-050 | 5 | 90 | 50 | 6.35  |

| 5-055 | 5.5 | 90 | 50 | 6.35  |

| 5-060 | 6 | 90 | 50 | 6.35  |

| 5-065 | 6.5 | 90 | 50 | 6.35  |

| 5-070 | 7 | 90 | 50 | 6.35  |

| 5-075 | 7.5 | 90 | 50 | 6.35  |

| 5-080 | 8 | 90 | 50 | 6.35  |

| 5-085 | 8.5 | 100 | 60 | 6.35  |

| 5-090 | 9 | 100 | 60 | 6.35  |

| 5-095 | 9.5 | 100 | 60 | 6.35  |

| 5-100 | 10 | 100 | 60 | 6.35  |

| 5-105 | 10.5 | 100 | 60 | 6.35  |

| 5-110 | 11 | 100 | 60 | 6.35  |

| 5-115 | 11.5 | 100 | 60 | 6.35  |

| 5-120 | 12 | 100 | 60 | 6.35  |

| 5-125 | 12.5 | 120 | 70 | 6.35  |

| 5-130 | 13 | 120 | 70 | 6.35  |

| 5-135 | 13.5 | 120 | 70 | 6.35  |

| 5-140 | 14 | 120 | 70 | 6.35  |

| 5-145 | 14.5 | 120 | 70 | 6.35  |

| 5-150 | 15 | 120 | 70 | 6.35  |

| 5-155 | 15.5 | 120 | 70 | 6.35  |

| 5-160 | 16 | 120 | 70 | 6.35  |

| 5-165 | 16.5 | 120 | 70 | 6.35  |

| 5-170 | 17 | 120 | 70 | 6.35  |

| 5-175 | 17.5 | 120 | 70 | 6.35  |

| 5-180 | 18 | 120 | 70 | 6.35  |

| 5-185 | 18.5 | 120 | 70 | 6.35  |

| 5-190 | 19 | 120 | 70 | 6.35  |

| 5-195 | 19.5 | 130 | 80 | 10  |

| 5-200 | 20 | 130 | 80 | 10  |

| 5-205 | 20.5 | 130 | 80 | 10  |

| 5-210 | 21 | 130 | 80 | 10  |

| 5-215 | 21.5 | 130 | 80 | 10  |

| 5-220 | 22 | 130 | 80 | 10  |

| 5-225 | 22.5 | 130 | 80 | 10  |

| 5-230 | 23 | 130 | 80 | 10  |

| 5-235 | 23.5 | 130 | 80 | 10  |

| 5-240 | 24 | 130 | 80 | 10  |

| 5-245 | 24.5 | 130 | 80 | 10  |

| 5-250 | 25 | 130 | 80 | 10  |

| 5-255 | 25.5 | 130 | 80 | 10  |

| 5-260 | 26 | 130 | 80 | 10  |

| 5-265 | 26.5 | 130 | 80 | 10  |

| 5-270 | 27 | 130 | 80 | 10  |

| 5-275 | 27.5 | 130 | 80 | 10  |

| 5-280 | 28 | 130 | 80 | 10  |

| 5-285 | 28.5 | 130 | 80 | 10  |

| 5-290 | 29 | 130 | 80 | 10  |

| 5-295 | 29.5 | 130 | 80 | 10  |

| 5-300 | 30 | 130 | 80 | 10  |

| 5-310 | 31 | 140 | 90 | 12  |

| 5-320 | 32 | 140 | 90 | 12  |

| 5-330 | 33 | 140 | 90 | 12  |

| 5-340 | 34 | 140 | 90 | 12  |

| 5-350 | 35 | 140 | 90 | 12  |

| 5-360 | 36 | 140 | 90 | 12  |

| 5-370 | 37 | 140 | 90 | 12  |

| 5-380 | 38 | 140 | 90 | 12  |

| 5-390 | 39 | 140 | 90 | 12  |

| 5-400 | 40 | 140 | 90 | 12  |

| 5-410 | 41 | 140 | 90 | 12  |

| 5-420 | 42 | 140 | 90 | 12  |

| 5-430 | 43 | 140 | 90 | 12  |

| 5-440 | 44 | 140 | 90 | 12  |

| 5-450 | 45 | 140 | 90 | 12  |

| 5-460 | 46 | 140 | 90 | 12  |

| 5-470 | 47 | 140 | 90 | 12  |

| 5-480 | 48 | 140 | 90 | 12  |

| 5-490 | 49 | 140 | 90 | 12  |

| 5-500 | 50 | 140 | 90 | 12  |

QTY(Inner Box):6pcs / 31mm~36mm 3pcs / 37mm~40mm 2pcs / 41mm and up 1pc

3pcs Set

| Product No. | Set | Description |

|---|---|---|

| 5-SA | A Set | 6・9・12mm(1pc) |

| 5-SB | B Set | 3・4・5mm(1pc) |

| 5-SC | C Set | 6・8・10mm(1pc) |

| 5-S090 | 9mm Set | 9mm(3pcs) |

| 5-S105 | 10.5mm Set | 10.5mm(3pcs) |

| 5-S120 | 12mm Set | 12mm(3pcs) |

QTY(Inner Box):6sets

Custom Auger Bits

Any Length and any size are available depending on your needs.

We can make various Auger Bits to comply with your needs.

Bits of knowledge

- When certain boring depths are needed, a Drill Stopper can be used.

Help

How to re-sharpen?

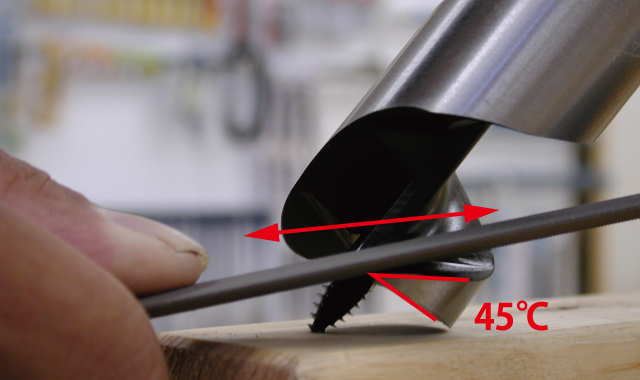

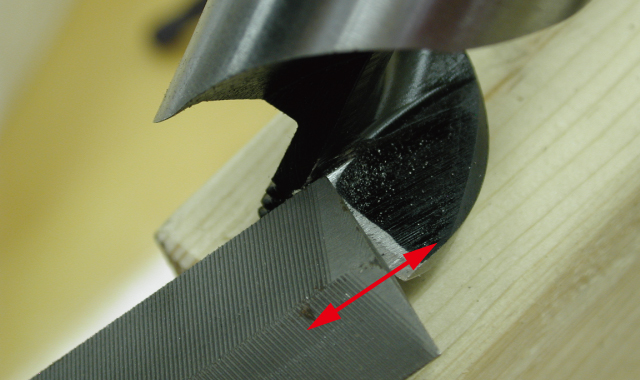

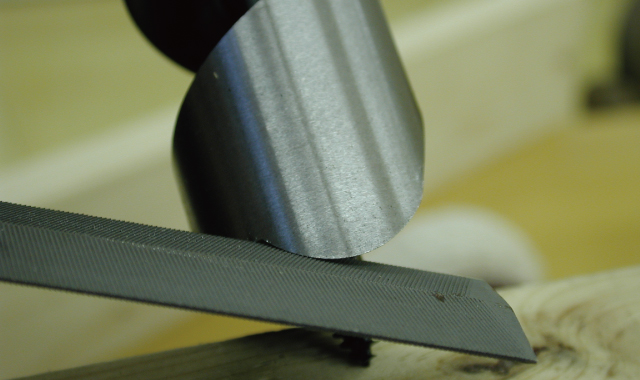

Sharpening the cutting edge

①Hold the bit as shown at approximately a 45-degree angle. Place the file at a near-horizontal position, making sure it is flush with the cutting edge.

②Touch the left edge of the file to the bit's spine, which will be used as a guide. File forward repeatedly only. Do not file in reverse.

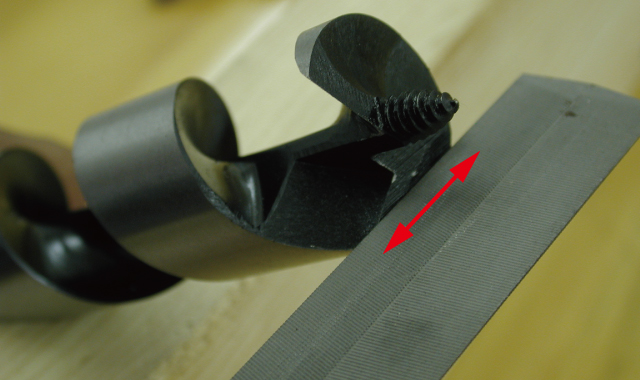

Sharpening the spur

① If the spur has any burrs, lightly file them to create a clean edge.

②Hold the bit so the side of the spur is facing up. Place the file flush with the spur. File with a smooth forward motion.

Associated Product